The Electronic Bubble Level

for builders and servicers of truck scales, tank scales and other industrial scales

Introduction

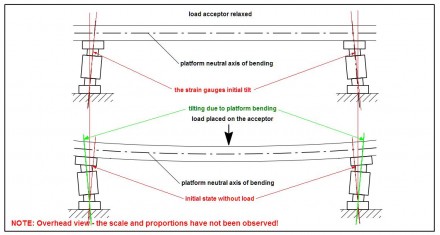

It’s common knowledge that companies installing and servicing multisensor platform scales and tanks scales often meet a problem of precise adjustment of the load cells. An inclination of the load cell working axis from the vertical results in various problems with weighing. Most common are: a weight indication decrease, an increased amount of errors due to the non-symmetric loading of the load receptor or an unacceptable instability of indications. These symptoms (usually appearing simultaneously) are often a cause of the consumer’s dissatisfaction and complaint. Such situation results in the Owner’s service call and the Contractor’s or the Servicing Company‘s visit to the place where the scale was installed, which is troublesome for both sides.

Such phenomenon, as an effect of the long-term exploitation of the scale, worries nobody but its Owner, but if it occurs at the very beginning of the scale’s operation or after servicing it can cause inconvenience to the Weigh Specialist, resulting in additional costs necessary to achieve the desired effect. These are constantly the same features such as: the stable weight indication, the repeatability of indications and the resistance to the typical conditions in which the scale is used.

My solution – the Electronic Level for scale builders – naturally doesn’t eliminate the load cells setting errors, but it allows judging quickly and accurately whether the sensor is correctly set, which is vertically. The setting errors in both perpendicular axes are clearly indicated, which is invaluably helpful in a size and direction adjustment of the sensor’s setting, needed to achieve the correct position.

There are manufacturers who claim their load cells are resistant to the inclination of the sensor working axis from the vertical even up to 5°. This is true on condition that the sensor has a constant setting for the whole time of working. In that case the load cell himself is working properly and only its output sensitivity decreases (proportionally to the cosine of inclination angle). We all know that this state is unreachable in practice, even if the load cell is located under the tank. Dynamic load changes naturally cause “swaying” of the sensor. Also the mutual setting is changed always when the ground (foundation), the load receptor and sensors altogether don’t create a perfect parallelogram – the most common situation in practice. Preventive tilt of the sensors (into upside-down “V” position) while assembling, recommended by some manufacturers, is also not a solution. It immediately raises a problem of achieving the symmetry of the settings, which can’t be solved only with measuring the distance between load cells’ supports. The range of applying the Electronic Level is wider than only to the service of truck and tank scales. Any kind of industry scale that uses analog or digital compression load cells, cylindrical in shape, can be efficiently assembled and maintained thanks to the proposed device.

The range of applying the Electronic Level is wider than only to the service of truck and tank scales. Any kind of industry scale that uses analog or digital compression load cells, cylindrical in shape, can be efficiently assembled and maintained thanks to the proposed device.

The concept of the level and load cell cooperation

The idea of measuring with the Electronic Level

Electronic Level uses a triaxial acceleration MEMS sensor. It is made with MEMS technology (micro machine produced as silicon integrated circuits), and it responds to the gravity vector position in three dimensional space. Signal from the accelerometer is converted into a digital value and then processed in an embedded microcontroller. Thanks to that, results can be presented in the form of displacement of the level “bubble” in two axes: longitudinal and transversal in relation to the foundation of the sensor. The design of the position sensor support (an innovatory swan shape) enables putting the Level to the load cell core or supports. Precisely crafted triangular measuring prisms with the angle of 120° provide a correct cooperation between the level and any cylindrical load cell with diameter of the circular core or supports ranging from 30mm to 90mm.

Parameters of the Electronic Level

Attitude sensor: LIS3LV02DL,

Sensor type: triaxial accelerometer with measuring range ± 2g,

Resolution of the acceleration measurement: 16 bits (214 LSB / g),

Resolution of tilt measurement: 0.06°,

Tilt measurement range: ± 3.2° in both axes,

Power supply: Li-Ion 3.7V 1000mAh / Charger Built-in

Indication: tilt in degrees and mm/m referenced to the 200mm base (typical height of the sensor with supports).

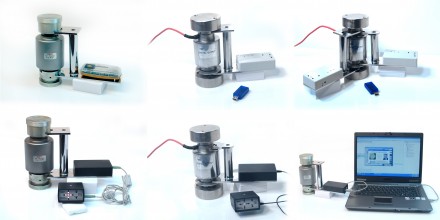

Variants of the device

Electronic Level is available in three versions of measuring module:

Level with a built-in graphic display with a touch panel (32-bit ARM microcontroller STM32)

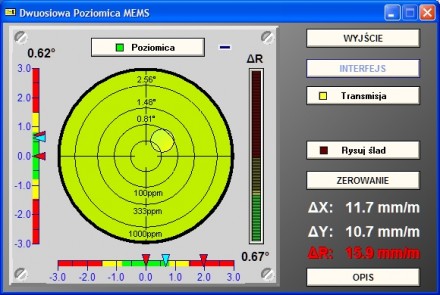

The Electronic Level display- the graphics mode, lateral deviation (X) and longitudinal deviation (Y)

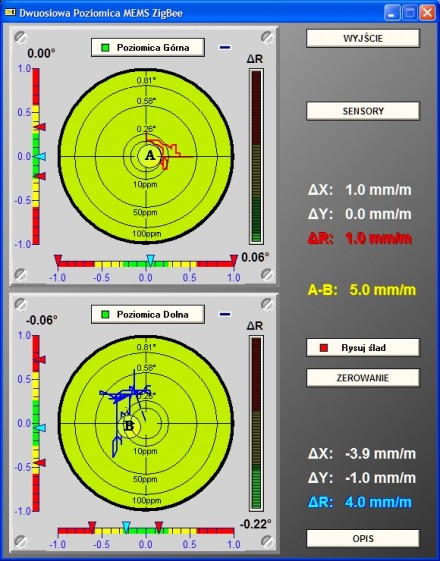

The Wireless Level (ZigBee), working with the visualization software via USB port.

This version of the Electronic Level can cooperate with the second level sensor. The software shows a difference of inclination between two level sensors. You can also visualize a trace of tilt position of the sensor(s) for example during a car’s going onto the load receptor.

Level wired with a detached visualization panel, working with the software via USB port.

In the wired version the resolution is raised to the level of 0.025 degrees.

The Electronic Level is available in two sizes

Level with 95mm opening width of measuring prisms

Adapted to cooperate with load cells of the families:

- ASC / DSC (Vishay / Revere),

- ASL / SCL (Precia),

- BM14G / BM14K (Zemic),

- C16A / C16i (HBM),

- CA40X (Scaime),

- RCP (Dini Argeo),

- SPA / SPD (Sensocar),

- ZSFA / ZSFY (KELI).

Level with 125mm opening width of measuring prisms

Adapted to cooperate with load cells of the families:

- ASC / DSC (Vishay / Revere) – applied to the supports of the LC,

- ASL / SCL (Precia) – applied to the supports of the LC,

- BM14C / BM14G / BM14K (Zemic) – applied to the supports of the LC,

- C16A/C16i (HBM) – applied to the supports of the LC,

- CA40X / CB50X (Scaime) – applied to the supports of the LC,

- RC3 (Flintec) – applied to the supports of the LC,

- RCK (Dini Argeo),

- ZSFA / ZSFY (KELI).

It is also possible to set-up with the Level other, so far not mentioned, load cells of similar size and way of fixing in the supports.

With the help of the Level, you can check vertical position of any round object with a diameter of 30mm – 90mm and traditionally you can level any surface.

On client’s request it is possible to prepare a Level’s support of any desired aperture of the measuring prisms.

The Electronic Level and the visualization software is designed and produced by the DSC Andrzej Jozef Majewski company from Gdańsk, Poland.

In case of any technical and commercial matters, please contact us.